Tailor-made performance

for every terrain to conquer

OUR EQUIPMENTS

YOUR STRENGTH ON THE FIELD

We manufacture equipment ranging from 0 to 7 tons in total weight, designed for machines with an operating weight from 1 to 100 tons.

Discover our complete range of special attachments, engineered to boost the performance of your earthmoving machines and simplify even the toughest jobs. From digging buckets to block lifting forks, each product is developed to ensure quality, efficiency, durability, and maximum productivity in any working environment, minimizing machine downtime.

Choose the right solution for your job site: we bring the quality and experience, you make the difference by choosing the best option.

Choose the right solution for your job site: we bring the quality and experience, you make the difference by choosing the best option.

Excavators

Services

Spare Parts

The right parts, no compromises

We stock a wide selection of original and compatible spare parts from the best brands for earthmoving equipment.

From wear parts to structural components, we guarantee availability, compatibility, and quality to keep your machines always performing at their best.

We also manufacture any type of bolt-on cutting edge or crusher/screen liner plates in HARDOX®450/500/500TUF.

We can reverse-engineer your samples and reproduce plates and assemblies carpentry in HARDOX® of any kind.

Riparations

We repair to make it last longer

We offer fast and reliable repair services for all types of equipment.

We work on buckets, forks, arms, and special attachments, restoring them to full working condition using skilled procedures, certified methods, and high-quality materials. Our goal? Minimize machine downtime and extend the useful life of your tools.

Used Equipment

Reliable quality, even over time

If you’re looking for cost-effective solutions without sacrificing reliability, our selected used equipment is the perfect choice.

Each item is inspected, refurbished if necessary, and tested to ensure high performance and maximum safety.

Ideal for those seeking smart investments with no compromises.

Who we are

Experience, innovation, and customer focus: this is where our work begins.

We have over 40 years of experience in the earthmoving sector, having operated as dealers of top-tier machinery, as well as repair and maintenance professionals, and now manufacturers of attachments that proudly bear our name.

For years, we’ve been supporting those who work daily on construction sites, in quarries, and in mines, understanding their needs and delivering specialized equipment for earthmoving machinery, built to last, perform, and adapt to any challenge. From buckets to forks, including spare parts, repairs, and certified used items, our goal is to deliver tailored solutions for every task. From buckets to forks, including spare parts, repairs, and certified used items, our goal is to deliver tailored solutions for every task.

We believe in quality workmanship, top-tier materials, and fast, responsive service.

Because for us, it’s not just about equipment: it’s about trust, collaboration, and results.

From raw material to finished product

every phase under control

Our production is entirely internal and covers all the fundamental phases for the creation of special equipment for earthmoving machines. This allows us to guarantee maximum quality, traceability and speed of execution, customizing each project based on the real needs of the customer.

1. Warehouse

We manage a fully stocked warehouse with sheets, semi-finished goods, and components to minimize lead times and optimize production flow.

On average, we stock around 250 tons of HARDOX®450/500/500TUF and HITEMP, and about 50 tons of structural steel.

Immediate availability of materials allows us to promptly launch every order.

2. Design

Each attachment starts with a careful in-house design process using the most advanced 3D CAD/FEM software and the experience of our technical team.

We develop tailor-made solutions to ensure strength, functionality, and compatibility with all types of machinery.

4. Plasma Cutting and Oxyfueling

We use high-definition plasma and oxy-fuel cutting technologies to accurately cut steel sheets of varying thickness.

This step is the foundation of production, where precision and speed make the difference.

5. Beveling

Edge preparation through beveling is essential to ensure high-quality welds.

We use dedicated machines to create clean, precise angles that enhance both appearance and structural integrity.

6. Bending

With a 4.0 precision rolling machine, we shape sheets into the required geometries.

This process ensures uniformity and repeatability even with complex shapes.

8. Welding

Welding is performed by certified, regularly trained professionals.

Each joint is executed with care and according to certified procedures to ensure structural integrity, durability, and safety under all working conditions.

9. After Sales

Our commitment doesn’t end with delivery.

We provide technical support, consulting, spare parts, and repair services to keep your equipment in top working condition.

You’re never left alone.

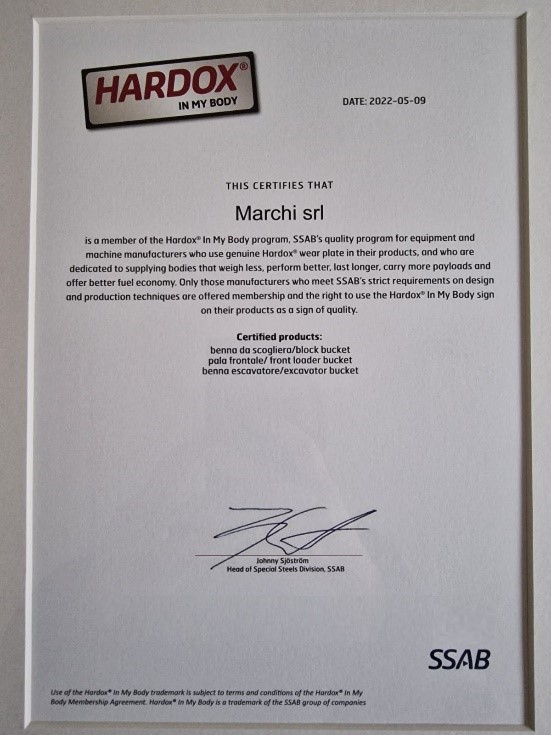

Certifications

In 2022, following an assessment of our projects, the Swedish steel manufacturer SSAB® certified our products with the HARDOX IN MY BODY label.

This recognition certifies the quality of our design and construction processes, as well as our extensive use of HARDOX® steel—confirming one of our founding principles: providing the highest construction quality to ensure long-lasting equipment and reduced downtime.

News

07/05/2025

New Website Online!

We are pleased to present our new website: completely renewed in graphics and contents, designed to offer you simple and intuitive navigation.

Here you will find all the latest information about our products — buckets, wheel loaders and excavator attachments — as well as a new section dedicated to the trade fairs and industry events we attend. Stay connected to not miss the latest news from our world!